Executive Summary

Supermarkets in humid climates need some way to reduce their in-store humidity levels, which can otherwise play havoc with the freshness of perishables and the efficiency of refrigeration equipment. Bel-Garden Bi-Rite, BJ’s Wholesale Club and Hy-Vee have each deployed a different dehumidification technology to address this issue. Desiccant systems (solid and liquid) absorb moisture in the air while air-conditioning systems can be equipped with reheating coils to dry the air. The ROI on the systems come from energy savings in the form of more efficient refrigeration racks, less defrosting of coils on refrigerated and frozen cases, and less use of anti-sweat heaters in frozen case doors, among other factors. The systems also help balance the air flow into and out of stores, preventing untreated outside air from getting in.

OVER THE NEXT FEW MONTHS, as temperatures rise in the city of Baltimore, so too will the humidity level, creating operational challenges for supermarkets like the 27,000-square-foot Bel-Garden Bi-Rite, a one-store family-owned operator.

OVER THE NEXT FEW MONTHS, as temperatures rise in the city of Baltimore, so too will the humidity level, creating operational challenges for supermarkets like the 27,000-square-foot Bel-Garden Bi-Rite, a one-store family-owned operator.

Until about two years ago, the humidity that seeped into the store caused a host of problems for co-owners (and sisters) Sandy Vary and Chrissie Bird, including wilted produce, shortened shelf life for meat and frozen vegetables, compromised photographic paper used for cake decoration, too-frequent defrosting of frozen cases, and shutdowns of the refrigeration system. Even copy paper would curl. The store’s two air-conditioning systems, despite expending considerable energy, were unable to adequately absorb the excess moisture.

And besides its depleting effect on food and energy, watery conditions pose another threat to retailers — slips and falls, and the legal liability that follows.

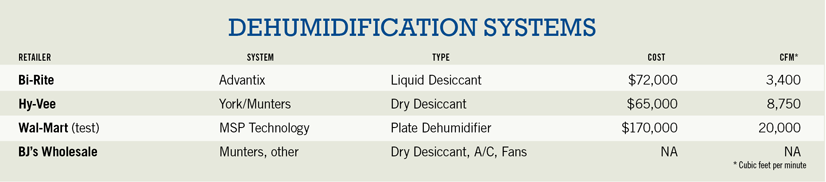

Vary and Bird looked into acquiring a solid desiccant system to dry the air, but found it too costly. But when the time came to replace one of their two air-conditioning units, they were presented with the opportunity to become one of the first supermarkets to use an off-the-shelf air-conditioning/dehumidification unit, from Advantix Systems, Sunrise, Fla., that employs a liquid desiccant technology. Despite some reservation about being a “guinea pig,” they went forward with the 3,400 cfm (cubic feet per minute) system in June 2011 — and solved their problems during peak humidity periods in the spring, summer and fall.

In Bi-Rite’s case, a new air-conditioning unit would have been 75% of the cost of the Advantix system (which was about $72,000, said Vary). However, Bi-Rite earned a rebate from Baltimore Gas & Electric that cut the cost in half. Even without the rebate, an ROI on the entire system would have been 2.5 years, said B.J. Elliott, president, Intelligent Power & Air Solutions, Spotsylvania, Va., which installed the Advantix system at Bi-Rite.

Following the Bi-Rite deployment, Elliott has just completed installing the Advantix unit in two of the three Geresbeck’s Baltimore supermarkets, which have large prepared food sections. The stores, like Bi-Rite, have experienced significant condensation issues on freezer cases, he said.

Vary sees the impact of the new system every day in the quality of perishables. “When you take out cases of frozen vegetables to stock, the ones that thaw the quickest — in the third or fourth case — would feel a little damp in the past, but we don’t experience that anymore,” she said. Moisture on fresh meat packages and green peppers has also disappeared. “In general, we get at least one more day out of [fresh] products,” she said.

Besides its positive effect on food, the system has shored up the store’s energy resources. Total annual energy savings is $32,287 to $33,287, according to Elliott. That calculation was based on the replacement of the existing system, raising the thermostat set point from 68 degrees to 75 degrees Fahrenheit, less frequent use of anti-sweat heaters, and an overall lower load on refrigeration.

“Managing humidity in the building is a good lever to save energy,” said Hannah Granade, president of Advantix Systems, adding that this opportunity has been under-utilized to date as retailers have focused on lighting retrofits and other initiatives.

While food retailers need to be sensitive to a host of conditions in their stores, humidity may be one of the more challenging to tame. “Handling humidity is the most expensive part of conditioning a building,” said Granade. “It’s the most difficult challenge with existing equipment.” Humidity is particularly elusive for air-conditioning systems in the “shoulder seasons” — spring into summer and summer into fall — when the humidity may be significant but the temperature is not that high, she noted.

But a wide range of systems are available to help retailers with this issue. Besides liquid desiccant systems like Advantix’s, there are dry desiccant systems, air-conditioning units modified to handle humidity and hybrid systems that combine different technologies. Several years ago, A&P, Montvale, N.J., installed in one store a PureComfort cooling, heating and power system (now marketed by Carrier) that includes dehumidification.

As BJ’s Wholesale Club, Westborough, Mass., added more frozen food and other perishables, it began to deal with humidity in greater earnest, said Joe Gallego, formerly BJ’s manager of refrigeration and HVAC services and now special projects manager, Bay State Cooling, Bridgewater, Mass. “[BJ’s has] really been addressing that issue over the past two years with great success and I see many other chains starting to look at dehumidification systems and controlling building envelopes.”

In particular, BJ’s has added dehumidification capabilities through the installation of dry desiccant systems from Munters, Amesbury, Mass., over the refrigerated foods section in about 10 clubs, said Gallego. By drying the air, the Munters units help the refrigeration and air-conditioning units work more efficiently, he noted, adding that BJ’s had to train its technicians to service the Munters technology.

In new BJ’s facilities, the company is installing air-conditioning systems with reheating coils that both cool and dry the air for the entire sales floor. The secondary coils reheat the dry air to room temperature. “The unit stays running; it doesn’t cycle off,” said Gallego. “It’s not the most efficient way but it does work.” Some food retailers use waste heat from refrigeration racks to reheat the dry air, but that increases the risk of refrigerant leaks, said Dave Kjelgaard, service manager for Bay State Cooling.

BJ’s has also installed Air Pear destratification fans, from Airius, Longmont, Colo., in a number of clubs to address condensation issues on the sales floor. The fans drive warm air from the roof down to the sales floor, and as the air rises it removes condensation on frozen case doors. “They take advantage of warm air already available,” said Gallego. “They work like a charm.” The fans also warm up aisles with frozen cases, making them more comfortable for shoppers. The fans are a lower-cost, lower-energy means of removing door condensation than anti-sweat heaters, allowing BJ’s to install doors without the heaters (except in the mullions), Gallego noted.

Lower-Energy System

Elliott explained that the advantage of the Advantix system is that in removing humidity it does not require additional energy to reheat overcooled air (as in an air-conditioning system with a large coil) or to cool down overheated air (as in a sold desiccant system).

By contrast the Advantix unit “takes outside air or building air directly to the desired humidity and temperature,” he said. It also operates more consistently, not spiking during peak demand during the summer as Bi-Rite’s conventional air-conditioning system did, which is “very appealing to utilities,” said Elliott. Just by replacing the previous system with the Advantix system, he said, Bi-Rite has saved, on an annual basis, 133,790 kilowatt-hours of power and $16,054 in costs.

Because of the Bi-Rite store’s relatively small size, the system handles humidity in the entire store. A larger format might be able to focus the system on the refrigerated cases only, said Granade.

The dehumidification system has also reduced the strain on the Bi-Rite store’s refrigeration system by reducing the amount of moisture and frost on evaporation coils in cases, as well as the number of defrost cycles. “This creates added capacity and energy savings for the [refrigeration compressor] racks,” said Elliott. He estimated that the annual energy savings for refrigeration, which accounts for half the energy consumption in a store, ranges from $6,000-$8,000.

The Advantix system is able to maintain the dew point — the temperature at which water vapor condenses into liquid water — in a supermarket at 50 degrees, which is the standard established by ASHRAE, noted Granade. “Anything north of that increases the load on the refrigeration system.”

Vary observed that the excess humidity had caused a significant increase in the icing of evaporation coils in coffin cases and some frozen-case doors, causing one section to shut down every three weeks.

“In the ice cream section, we would have problems with coils icing up,” said Vary. “And we would struggle with having enough defrost cycles without compromising products.” During the summer, the store would handle three defrosts per day to prevent the coils from icing. It was an arduous process. “You’ve got to remove the product from the case, put warm water on the coils. Sometimes the water would leak onto the floor and create a hazard. Not to mention that the products were so compromised you normally had to throw them out.” Often this would take place at inopportune times, like weekends. “It was just a nightmare,” she said.

But last summer, with the new system, “there was not one time we had to defrost coils as a result of the coils icing up from humidity,” she said. (The cases still required normal maintenance.)

Humidity also forced the store to keep the inside temperature lower than it had to be; the Advantix system has enabled Vary to raise the thermostat set point in the summer from 68 degrees to 75 degrees Fahrenheit, saving 13,475 kilowatt-hours and $1,617 annually, according to Elliott. “This creates a more desirable environment for shoppers,” he said. “They don’t need a jacket in the freezer section in the summer.”

Another big energy drain was the operation of anti-sweat heaters, which prevent condensation build-up — and product-blocking fog — on freezer case doors. “We were able to reduce the run time of the heaters, which was a huge savings for us,” Vary said. Less use of anti-sweat heaters has cut 63,466 kilowatt-hours annually, a savings of $7,616, which also helped earn the store its utility rebate, said Elliott. Anti-sweat heaters need to be used less because, for 98% of the time, the relative humidity in the store is kept below 50%, a comfortable level for shoppers, he explained. “Forty percent relative humidity is where we want to be to avoid having the anti-sweat heaters cycling on and off,” said Elliott.

Bi-Rite’s dehumidification system also removes bacteria, mold, odors and most particulates from the air. “It’s good to know [the store’s] air is a much purer quality than what’s typically out there,” said Vary.

By bringing in outside air, the system helps balance the air pressure in the store, which keeps untreated humid outside air from infiltrating the store. Many stores in humid summer climates, which include much of the country outside of the West and Southwest, experience infiltration of humidity via frequent opening of front doors (even those with vestibules) as well as dock doors and other entrances. Most retailers are reluctant to make the large investment required to tighten their store envelope, opting instead to address the issue when the time comes to replace mechanical HVAC systems (as Bi-Rite did), noted Elliott, adding it should also be considered during new construction.

Air infiltration has become more of an issue for the many supermarkets that are offering prepared foods because the air exhausted from kitchens pulls in outside air. “Retailers are not giving consideration to what [dehumidified] makeup air is needed,” said Elliott.

Bi-Rite’s in-store kitchen, which prepares a large amount of fried chicken, is located near an air-conditioning unit that removes some of the hot air from the kitchen, further compromising the air balance in the store. The dehumidification system “helps mitigate that,” said Vary.

Vary was initially concerned about the “hazmat” implications of the lithium chloride solution used by the system but learned that it is completely non-hazardous. Maintenance of the system has also proved to be minimal, with annual checks and occasional filter changes.

The dehumidification system has “never failed,” said Vary — alleviating her concerns about using a “bleeding edge” technology that had not been installed at another supermarket. “It went in seamlessly and the transition was seamless.” Though the system was new for a supermarket, it had a long track record in larger applications, including skating rinks, which reassured Vary and Bird, who were figure skaters when they were young.

Hybrid Approach

Hy-Vee, West Des Moines, Iowa, uses a different dehumidification system but one that is also geared around achieving a 50-degree dew point (about 45% relative humidity at 73 degrees Fahrenheit) in stores, said Jon Scanlan, director, refrigeration and energy management for Hy-Vee. “It’s what everything is set to,” he noted last fall at the Refrigeration Roundtable hosted by SN and ContractingBusiness.com. “There are not too many issues with that at all.” The 50-degree dew point maintains an optimal level of moisture for the store’s refrigeration system, with higher levels requiring more refrigeration energy and lower levels offering diminishing refrigeration energy savings and higher HVAC energy costs.

Hy-Vee’s stores, which typically encompass about 85,000 square feet, have evolved from using one or two large HVAC units on the roof to using multiple (three to four), packaged units from York, Norman, Okla., at least three of which are installed in series with Munters HCU desiccant units. The Munters units are “excellent at pre-treating outside air and controlling humidity while the packaged rooftop units are cost effective for air distribution and temperature control,” said Scott Jasper, HVAC business manager, Hussmann, Des Moines, Iowa, which is responsible for HVAC technology installed at Hy-Vee stores. The Munters units are about $45,000 apiece, while the York systems are each $20,000. Together they deliver 8,750 cfm of air to the store.

A 2005 study found that the hybrid HVAC/dehumidification systems cut energy consumption at a Hy-Vee store in West Des Moines by 2.5%, an annual savings of $27,410 compared to the code-required system; at a store in Sioux Falls, Iowa, the hybrid units reduced energy consumption by 1.4%, an annual savings of $16,570.

The multiple hybrid systems, distributed across the sales area, also have smaller and shorter duct runs in the store, reducing sheet metal costs, Jasper told SN. The systems are also good for matching particular cooling/dehumidification loads in a store — thereby saving energy — and for “minimizing the effects of a mechanical failure.” Jasper noted that the units are needed to address the entire store’s sales area, which has refrigerated merchandise distributed throughout. The system helps condition air across a wide range of weather conditions in the Midwest, from -15 degrees to 95 degrees Fahrenheit.

Most importantly, the hybrid system keeps the dew point temperature “a little below 50 degrees,” said Jasper, adding, “If you can run a 50-degree dew point store, you are generally considered on target.” That temperature provides a “cushion” that handles moisture from people in the store, produce misters and untreated infiltrating air. It helps the store weather the worst-climate days while providing a sound footing for the rest of the year, he observed.

The Hy-Vee stores with a 50-degree dew point “have very few callbacks and operate very well.” He estimated that the system contributes to a “moderate level” of defrost cycles but could not comment on its effect on the use of anti-sweat heaters in freezer doors.

Read more: Contractors Ask for More Start-Up Time

Jasper noted that stores all over the U.S. miss the 50-degree dew point because they are incorrectly designed, allowing moisture-laden air to enter the store. Engineers who are not familiar with supermarkets may lack an understanding of “how to bring in air properly and what controls are needed to maintain a 50-degree dew point.”

The hybrid systems also satisfy a store’s need for outside air, both to maintain indoor air quality (and meet ventilation codes) and to provide makeup air to balance in-store exhaust systems. “When you walk through a new Hy-Vee store you see a lot of kitchen hood systems” Jasper said. ”These hoods are visually interesting and create customer excitement for prepared foods.”

It is hard to build a supermarket that’s air tight, Jasper noted. Thus, trying to establish a positive air balance (the sum of outside air intakes exceeds the sum of building exhausts) in the store is like “trying to blow up a balloon with holes in it.” It is more realistic to design building HVAC systems to achieve a neutral air balance (the sum of outside air intakes equals the sum of building exhausts). Since building moisture is controlled, a moderate amount of infiltration air (say, due to wind pressure) can be tolerated, he said.

Sidebar: Wal-Mart's Puerto Rico Experiment

Down in Puerto Rico, Wal-Mart Stores is testing an unorthodox — for supermarkets — dehumidification system.

Over the past year, Wal-Mart has used the system, a roof-mounted plate dehumidifier from MSP Technology, Huntington, N.Y., at one supercenter and one Sam’s Club, replacing Munters desiccant systems that were out of service.

Edgardo Velez Saez, president of Quantum Consulting Engineers, San Juan, Puerto Rico, serving as a consultant to Walmart Puerto Rico, helped in the selection of the MSP unit among three alternatives. The 20,000-cfm (cubic feet per minute) MSP system, which cost about $170,000, “had the lowest consumption of energy,” he said.

About six months ago, Saez measured the dew point temperature in both stores and found it to be at “acceptable levels” — between 50 and 52 degrees Fahrenheit — and also required minimal maintenance. He said Wal-Mart is also using HVAC units from AAON, Tulsa, Okla., in other Puerto Rico stores. Wal-Mart did not respond to a request for comment.

Walter Stark, president of MSP Technology, noted that Wal-Mart’s dry desiccant systems require heat — derived from gas or electric energy — to remove moisture from the desiccant material. By contrast, the MSP unit pre-cools the air through a plate heat exchanger, thereby saving energy, and then sends it through a cooling coil for dehumidification and back to the heat exchanger, before being delivered to the store “cool and dry,” he explained. No energy is needed to reheat the dehumidified air before it enters the store.

The MSP system uses only refrigerant for dehumidification and saves on maintenance by “having no moving parts in the dehumidification process,” said Stark. The system is generally focused on managing humidity in the frozen-food area, where it is able to get the dew point temperature down to between 40 and 45 degrees. The lower humidity results in fewer defrost cycles in the frozen cases, he added.

| Suggested Categories | More from Supermarketnews |

|

|

|

|